OEMs in almost any part of the industrial world are facing an urgent requirement to reconfigure their approach to product development. In even the recent past, a viable business could be built on the provision of electronics products that were unconnected to any network, included little or no security functionality, and gave little scope for user interaction and control beyond a few mechanical buttons or levers.

All the trends in the industry are driving OEMs away from this model, and towards the development of products which are continuously hooked up to the internet, which transfer encrypted streams of data to other devices or to a cloud server, and which offer a graphics-rich window on their operation, supported by intuitive means of control such as a touchscreen and natural speech recognition.

This trend is having a dramatic impact on the constitution of OEMs’ development teams, and on their management of the development process. OEMs are finding that, for the first time, they need expertise in hardware and software functions such as wireless connectivity, encryption and authentication, and graphics displays and touchscreens. It is not easy to recruit and integrate designers with prior expertise in these areas into an established development team. Another option – equipping existing members of the design team with expertise in these new areas – takes a great deal of time and investment in training and skills development. The third option is to draw on the expertise of third-party partner companies which have specialist expertise in particular functions. Again, it takes time to carefully select a trusted network of third parties with the required skills.

Now help in solving this problem is coming from an unexpected direction: the component distributor.

It is unexpected, because distributors’ core competence is not normally thought to be product development and engineering resource management. Distributors’ expertise in the past has been primarily in the stocking and shipping of components, and in their marketing, including engineering-led product promotion and technical support. These component-level functions do not require system development know-how.

So what makes a distributor a useful resource for solving today’s product development difficulties?

Functional blocks common across many sectors of industry

The issue for OEMs is that they are having to supplement their traditional core product with a number of complex new functions for which they have not previously required development expertise. These functions typically include:

- Wireless connectivity – Bluetooth® Low Energy or Wi-Fi® radios for short-range connectivity, LoRaWAN™, Sigfox or NB-IoT for long-range networking

- Wired connectivity – typically Ethernet for internet connectivity, or USB for local connections, as well as industrial field buses such as Profibus and CAN

- Security – authentication and cryptographic functions, including authentication hardware to secure sensitive information or data traffic, and anti-tamper capability to protect the device itself, the system and hence the manufacturer’s brand

- Human-Machine Interface (HMI) – touch-sensing user inputs such as a touchscreen, and a graphics display

- Standards-compliant digital power supplies offering high efficiency, optimised power density and the ability to configure operation in response to operating conditions

The interesting characteristic of all of these functional blocks is that they are common to many end products and sectors of industry. This means that a third party, such as a component distributor, can potentially provide a single design platform or template for each function that could be used in hundreds of different end-product prototypes.

In doing so, the third party can draw on specialist expertise in these common functions to complement the applications expertise that the end-product manufacturer maintains. This was the intention behind the development by Future Electronics of its Centres of Excellence, design laboratories which bring together domain specialists who can help customers with development projects. In some cases, a Centre of Excellence provides in-depth system design support to enable the customer to implement the design of a specific functional block faster than it could alone, and with reduced development risk.

Future Electronics has four European Centres of Excellence:

- Paris, France – for sensors and connectivity

- Munich, Germany – for motor control and industrial systems

- Gdansk, Poland – for embedded systems

- London, UK – for power electronics

The service provided by the Centre of Excellence allows customers to concentrate on their core competence, and to get to market faster with new smart products, often with an option for internet connectivity, while eliminating design risk.

This service includes the provision of function-specific development boards designed and manufactured by a Centre of Excellence. These include boards for:

- Many types of motors

- Human-machine interfaces and sensors

- AC-DC and DC-DC power supplies with or without power factor correction, and inverters

- Connecting to the IoT

- High-end embedded computing operations using FPGAs

The boards provide an accelerated prototyping platform, giving an application-specific platform which may readily be modified and adapted to meet specific application needs. A Future Electronics Centre of Excellence is also able to assemble an ecosystem to bring to the customer qualified partners in specific technologies. These partners can include IP providers, developers of software building blocks such as display graphics, professional training providers and so on.

And while it might seem surprising at first that a distributor takes on the role of development board manufacturer, there is in fact a good basis for its suitability. First, the Future Electronics boards can use the newest components that have the best features and performance, because distributors have privileged access to component manufacturers’ roadmaps, and can integrate a new part into a board design before the part is officially launched.

Second, a distributor can ensure that every component on the board is optimised in terms of performance, availability and price. Unlike a component manufacturer, which will populate an evaluation board with parts from its own portfolio, a distributor’s board design can use the most suitable part on the market. As a broadline distributor, Future Electronics can choose from a very broad range of franchised suppliers when selecting components for its own board designs.

Third, a distributor can orient the specification of its board towards a particular function or application, whereas a component supplier’s evaluation board has a different purpose: to demonstrate in the most flattering way possible the features and performance of the main component. A function board will therefore include the various analogue and digital peripherals, interfaces and software required in an application – features that a manufacturer’s cost-optimised evaluation board will omit.

and get your PCBA quote within the next 10 minutes!

Platform design for graphics displays

The most recent addition to the Future Electronics portfolio of function boards is the Amber platform for Human-Machine Interface (HMI) design. At the heart of the Amber platform are three display controller boards, each based on a microcontroller with special graphics capabilities – the MCUs are supplied by STMicroelectronics, NXP Semiconductors and Microchip. The controller boards control a 4.3” or 7” industrial Liquid Crystal Display (LCD) from Tianma, with or without capacitive touch-sensing capability and with or without wide-angle viewing capability.

The Future Electronics Amber HMI design platform

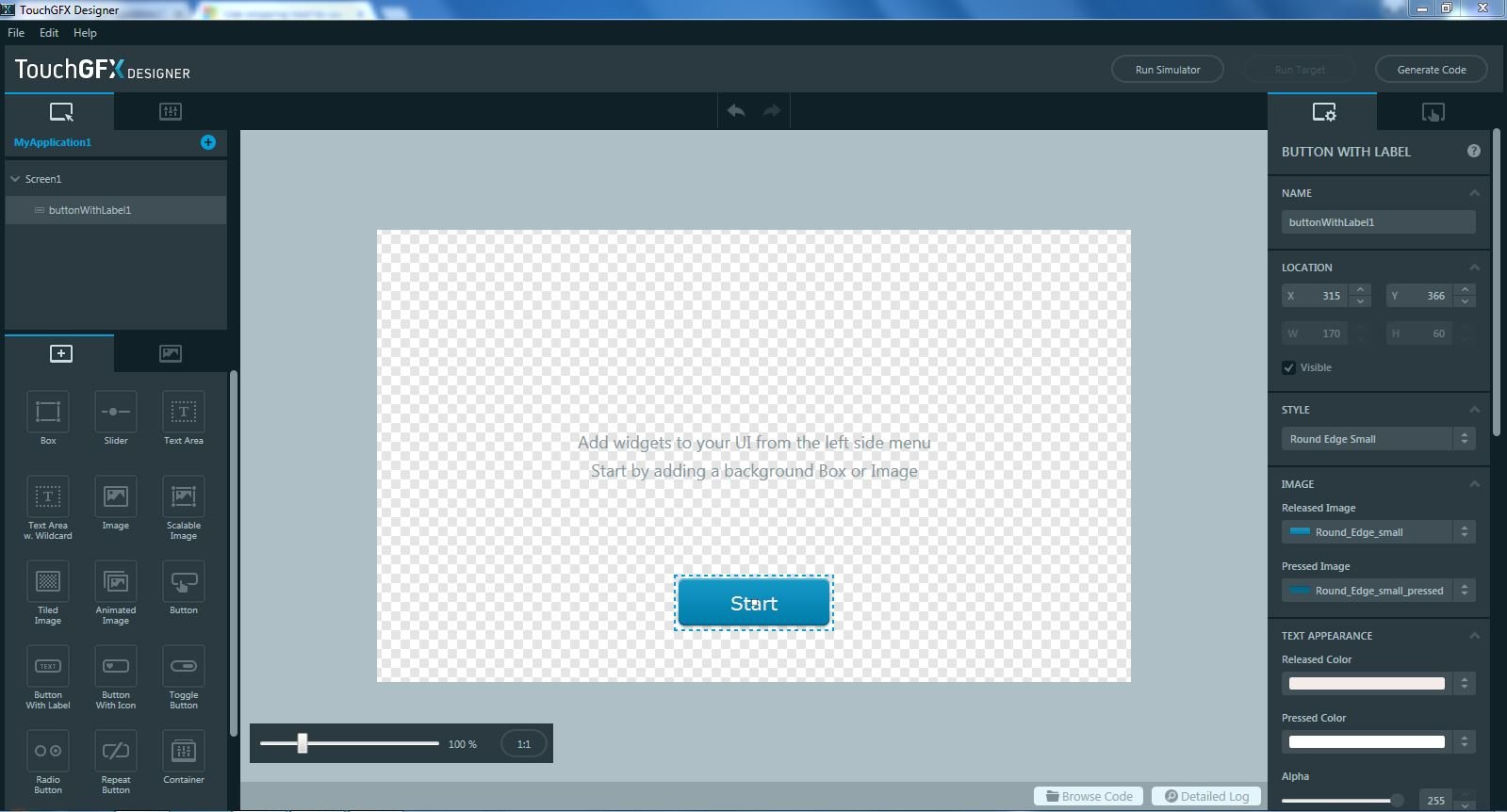

Crucially, the Amber platform enables the user to start working on graphics display UI development out of the box using the supported TouchGFX graphics design tool suite. The platform provides a real-world demonstration of the differences between different display configurations and of the capabilities of the TouchGFX tool. It also provides a much more intuitive way to evaluate display performance than research based on published display specifications.

Like every function board, the Amber platform is also backed by various Future Electronics training resources, information sharing on new product introductions, and technical support services.

The TouchGFX graphics design tool

Development process optimisation

In recent years, electronics OEMs have got used to the idea of the distributor extending its role from the mere shipment of components to a position as the supply-chain partner of manufacturing customers. By providing services such as the holding of bonded inventory, materials requirement forecasting and added-value logistics, the distributor now acts for some customers as a service provider offering supply-chain optimisation.

With the development of specialist function-specific design services and development platforms, it might be that distributors are extending their role in a new dimension, becoming a service provider offering development-process optimisation. Because of the common need for certain functions shared by many OEMs, distributors can step in to provide function boards and domain expertise, saving each individual customer the need to reinvent the wheel.

This eliminates design effort, gives customers access to sophisticated capabilities in an off-the-shelf board format, and thus accelerates time-to-market for new smart, connected products ready for the IoT and a new generation of demanding, tech-savvy end users.

By Etienne Lanoy,

By Etienne Lanoy,

EMEA Centre of Excellence Manager, Future Electronics

www.futureelectronics.com