There are several terms to define this category of printed circuit boards, such as Metallic PCB, Insulated Metal Substrate (IMS or IMPCB), Metal Core PCB (MCPCB), Aluminum Clad, Aluminum Base, and more. Although apparently different, all these definitions refer to the same type of PCB, whose technical characteristics and benefits are identical. Compared to traditional FR-4 epoxy glass-based PCBs, metallic PCBs first and foremost offer greater heat dissipation, thanks to 5 to 10 times higher thermal conductivity and up to 10 times less thickness with respect to conventional architectures. The particularly efficient transfer of thermal energy allows metal PCBs to use very light copper layers, reducing both costs and thickness of the solution.

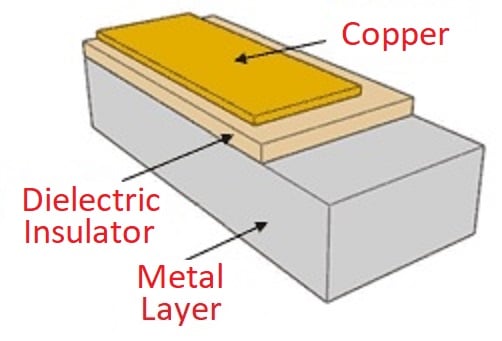

Metal PCBs are composed of a dielectric layer capable of offering high thermal conductivity (and therefore high dissipation), a metal layer and a copper film with high heat dissipation capacity and mechanical strength, used for circuit lithography. The most widely used materials for metal layer fabrication are aluminum and copper, but stainless steel can also be used in some applications. Copper offers superior performance and electrical properties than aluminum, but its cost is relatively higher. The metal layer can be composed entirely of metal, or a combination of fiberglass (FR-4) and metal. Metallic PCBs can then be single-sided or double-sided, while the multilayer version is less common due to its high manufacturing complexity. In the case of a multilayer MCPCB, the layers must be uniformly distributed with respect to the inner metal layer; for example in a PCB with 12 layers, the metal layer will be placed in the center of the stack-up, with 6 layers above and 6 layers below it.

Since metal is able to easily transfer heat by subtracting it from high-power components, typical applications of metal PCBs include power supplies, power converters, LED lighting systems and power circuits in automotive environments (headlights, lights, cooling, climate and more). This type of technology, in addition to efficient thermal management, allows to extend the components lifetime (such as LEDs), improving the reliability of the overall circuit.

Structure and applications

MCPCB technology, initially introduced in the 1960s for high power applications, is today widely used in applications where a reduced operating temperature must be maintained. The dielectric insulation material, which is the core of any metallic PCB, is designed to offer thermal conductivity (typically between 1W/mK and 9W/mK) much higher than that of the FR-4, allowing for efficient heat removal. The high thermal conductivity and the reduced thickness of the insulation layer (the standard measure is 100µm) allow a quick and effective transfer of the developed heat. A commonly used thermal conductivity value for the dielectric layer is 2W/mK, a much higher value than that of the FR-4. The best results are obtained by keeping the dielectric layer as thin as possible. In fact, this allows to minimize the path of heat dissipation from the points where it is generated up to the metal layer, which is several times more conductive, from a thermal point of view, than the dielectric material.

The structure of a classic metallic PCB is shown in Figure 1. The upper layer is formed by a thin copper film on which traces will be etched as occurs in conventional printed circuit boards. The typical thickness of this layer is between 1oz and 4oz, but it can also be greater. The innermost layer is represented by the dielectric material, whose function is to electrically isolate the metal layer from the copper film, while allowing rapid heat transfer between the two layers. Finally, we find the metal layer which, in most cases, is made of aluminum, with a thickness between 1mm and 3.2mm (the typical value is 1.6mm).

Figure 1: Typical structure of a metallic PCB.

The main applications of metal PCBs include LED lighting, motor control in electric and hybrid vehicles, solid state relays, power supplies, converters, voltage regulators, solar panels, and photovoltaic cells. More generally, this technology is suitable for applications that require a lot of energy and, therefore, generate a lot of heat. If the PCB requires fast cooling, it is better to use a metal PCB rather than a traditional FR-4 substrate. Aluminum, the metal most widely used for the metal layer, has very advantageous electrical characteristics, including excellent thermal conductivity, between 5W/mK and 2W/mK (Watt per meter Kelvin), high breakdown voltage (3kV and more) and high tensile strength.

Top 5 Advantages of MCPCBs

In addition to excellent thermal dissipation, metal PCBs offer higher power density, high electromagnetic shielding, and better capacitive coupling. Thermal performance can be further improved by using thermal vias, as happens in traditional PCBs. The five main benefits of this technology will now be listed.

1 – Thermal Dissipation

MCPCBs are one of the PCB options with higher thermal conductivity. By keeping the heat away from the power components as much as possible, they avoid possible damage to the circuit, being able to handle high density circuits with higher power levels. Aluminum is one of the most used materials for this type of substrate: in addition to its electrical properties, aluminum has the advantage of being recyclable and of low cost. Metal core PCBs transfer heat 8 to 9 times faster than PCBs made with FR-4. The dielectric layer must be very thin to create the shortest path from the heat source to the supporting metal plate. Its thickness is normally between 0.003 and 0.006 inches. As an example, consider that a test conducted on an MCPCB with integrated 1W LED showed how its temperature remained pretty close to the ambient temperature of 25°C, while the same power LED mounted on a FR-4 board reached a temperature 12°C higher than the ambient one.

2 – Better Strength and Stability

The recent and rapid development of LED technology, especially with high power LED lighting, has raised concerns about heat dissipation. Since they are usually mounted directly on the PCB, these LEDs can create stability and reliability problems for the circuit. Without adopting the right technique, heat dissipation can hinder the performance of electronic devices that operate at high power. The use of metal PCBs in these applications effectively solves this problem. In addition to ensuring a high durability, aluminum is very light, and adds strength and resilience to the printed circuit board without causing an increase in weight.

3 – Dimensional Stability

The size of a metallic printed circuit board remain more stable, as environmental conditions vary, than that of a PCB made with traditional materials, such as FR-4. Subjected to a heating process from 30°C to about 150°C, PCBs with metal layers (such as aluminum) have undergone a very small variation in size, ranging from 2.5% to 3.0%.

and get your PCBA quote within the next 10 minutes!

4 – Lower Weight and Higher Recyclability

PCBs with metal substrates are lighter, last longer, and are more conductive than traditional PCBs made from epoxy materials. In addition, they are more environmentally friendly, as the metals used, including aluminum, are non-toxic and are easily recyclable. Aluminum is very easy to mine and refine, which makes it considerably less expensive than other metals. Consequently, the manufacturing costs associated with PCBs using aluminum substrates can also be reduced. Aluminum PCBs are also a cost-effective alternative to more expensive and bulky heat sinks. Notoriously, aluminum is a non-toxic and totally recyclable metal. In the chain that connects the producer with the final consumer, the use of aluminum in metallic PBCs contributes to the safeguarding of our planet.

5 – Longer Lifetime

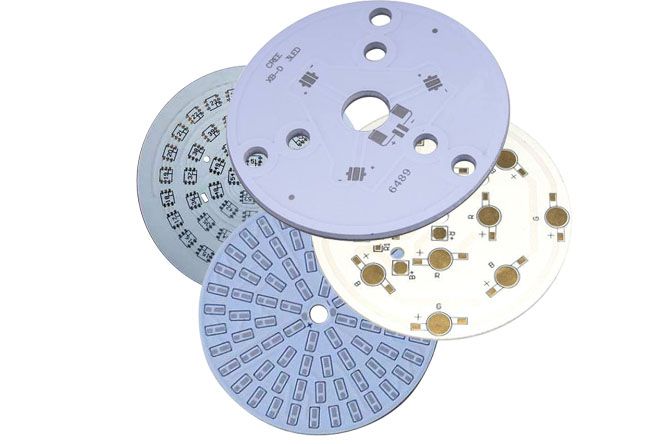

Aluminum offers greater strength and durability than materials commonly used in PCB fabrication, such as ceramic and fiberglass. It is a very robust metal capable of reducing the risk of accidental breakage that may occur during the various stages of production, during assembly or during normal use of the final product. Figure 2 shows some examples of aluminum PCBs for applications in the field of LED lighting.

Figure 2: Some examples of aluminum-based PCBs.